空心杯驱动电机KPD10A-1020

深 圳 市 坤 鹏 达 机 电 有 限 公 司

SHENZHEN KUNPENDA MACHINERY & ELECTRONICS CO., LTD

产 品 规 格 书

PRODUCT SPECIFICATION

|

客户信息 |

客户名称/Customer |

|

|

客户料号/Part No. |

|

|

客户承认签章Customer Approved Signatures |

|

|

品名/Description |

空心杯直流电机/ Coreless cup DC Motor |

|

型号/Part No. |

KPD10A-1020 |

|

版次/Rev. |

A/0 |

|

设计/Designed |

审核/Checked |

批准/Approved |

|

张文 20170405 |

刘华 20170405 |

杨广 20170405 |

址: 地址:中国深圳市宝安区石岩镇官田华丰科技园B4栋3楼

电话 / Tel : (0755)26554791

电子邮箱 / E-mail: 13828794968@126.com

传真Fax:(0755) 26559653

重要提示 IMPORTANCE NOTES:

1. 如对电机的性能或寿命有任何争议,仅基于此规格书作出判断。 If there is any argument on motor performance or life, judgment is to be made base on this specification only.

2. 客户方有责任确认该电机能满足您的使用要求。 Customer has the responsibility to ensure that the motor can satisfy the requirement of your application.

3. 如果贵公司未提供技术规格,该文件将详细叙述与贵公司商定的技术规格。 In the event that an official specification is not present by customer; this document will specify the agreed technical specification.

4. 收到此规格书后,贵司应于下订单之前将规格书副本签回以示贵司已确认。如贵司未能在规定时间内签回副本,我司将认为贵司已收到并承认该规格书。 After the receipt of this specification, customer should send a signed copy to KINGWE before you issued purchase order for the confirmation on acknowledgement. KINGWE regard it as the receipt of this specification acknowledged if customer fails to return the confirmation to us within the described period.

更 改 记 录

Revised Record

|

版次Rev. |

日期 Date |

更改原因

Reason for change |

编制Designed |

审核Checked |

批准Approval |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. 适用范围 General

本规格书适用于空心杯直流电机KPD10A-1020型号。

This specification applies to Coreless cup DC motor KPD10A-1020 model。

2. 结构形式 Construction-form

|

序号NO. |

项目

Item |

内容

Contents |

|

2-1 |

电机结构

Motor construction |

直径为10mm的空心杯直流电机

10mm cylindrical Coreless cup DC motor |

|

2-2 |

磁极极数

Number of magnet poles |

2极(磁钢内置)

2-poles(inner magnet type) |

|

2-3 |

换向方式

Rectifying method |

金属电刷换向器装置

Metal brush and commutator |

3. 标准使用条件 Standard operating condition

|

序号NO. |

项目

Item |

规格

Specification |

条件/备注

Condition / Remark |

|

3-1 |

额定电压

Rated voltage |

DC3.7V |

马达导线两端静态电压

The two ends of the wire quiesceng voltage motor |

|

3-2 |

额定负荷

Rated load |

风叶

The blade of the fan |

封样风叶

The blade of the fan |

|

3-3 |

旋转方向

Rotation direction |

顺时针方向

CW |

由出力轴方向目视

As seen from shaft |

|

3-4 |

摆放位置

Motor position |

任意位置

Any position |

|

|

3-5 |

使用电压范围

Operating voltage |

DC2.5V~4.0V |

用户使用的产品负载不同,该使用电压范围只作参考值,无任何承诺意义

As the customers actual load is different, this working voltage range is just for reference |

|

3-6 |

使用环境

Operating conditions |

-10℃~50℃

15%~95%RH |

常规湿度/ordinary humidity

不凝露/no condensation of moisture |

|

3-7 |

贮存环境

Storage conditions |

-20℃~60℃

15%~75%RH |

常规湿度/ordinary humidity

不凝露/no condensation of moisture/ |

4. 产品测试环境条件 Environmental Test Conditions

|

序号NO. |

项目

Item |

测试环境条件

Environmental condition |

|

4-1 |

温度

Temperature |

20±3℃ |

|

4-2 |

湿度

Humidity |

60±5% RH |

|

4-3 |

电机体位

Motor Position |

轴伸水平

Shaft Horizontal |

|

4-4 |

电源

Power Supply |

直流稳压电源/DC Power Supply DC3.7V±2% |

备注:所有的数据在温度20±3℃,湿度60±5% RH的条件下测定。在对判定不发生异议时,也可在温度5~35℃,湿度45~85%RH的环境下测试。

NOTE:All data shall be based on the measurement under the temperature 20±3℃ and humidity 60±5% RH, however the range of temperature 5~35℃ and humidity 45~85%RH if there is no doubt about the judgment.

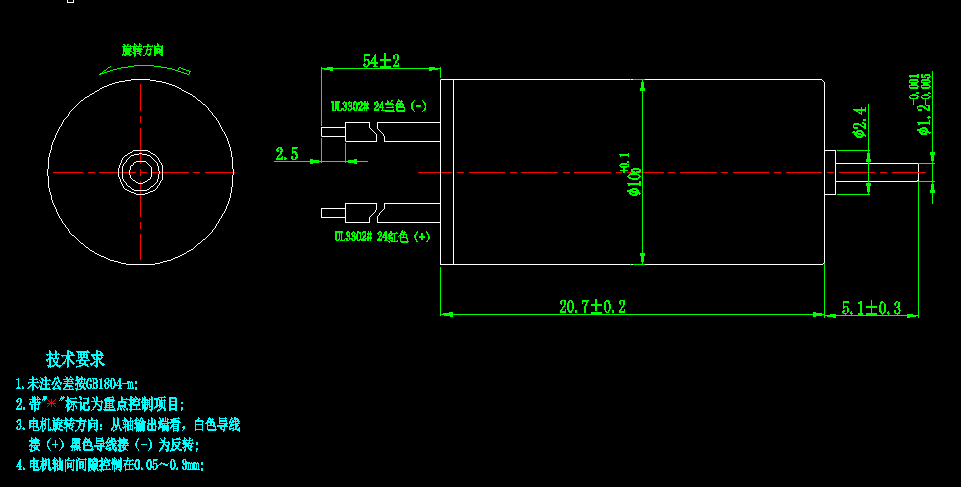

5. 机械特性 Mechanical Characteristic

|

序号NO. |

项目

Item |

测试环境条件

Environmental condition |

规格

Specification |

|

5-1 |

外观尺寸Configuration |

游标卡尺

Vernier caliper |

参考外形图纸

As specified in outline drawing |

|

5-2 |

外观Appearance |

目测

Visual examination |

无明显机械划痕、裂缝、锈迹、污点

No obvious evidence of mechanical damage、crack、rust and stain |

|

5-3 |

重量

Weight |

架盘天平 精度0.1g

Plate balance 0.1g |

8g(Approx)

(左右) |

|

5-4 |

轴向间隙

Shaft end play |

游标卡尺或百分表

Vernier caliper or Dial indicator |

0.3mm Max |

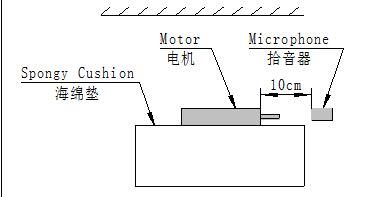

5-5

|

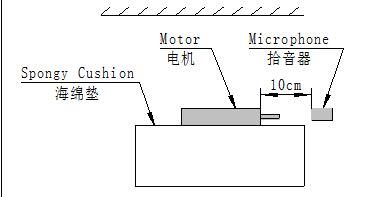

机械噪声Mechanical

Noise |

测试场地:类半自由声场

额定电压,空载运行,背景噪声≤23 dB(A),电机固定在测试夹具上(轴伸水平),拾音器沿轴向正对电机平面,距离10 cm。Test site: Class of semi-free field

At rated voltage and free load, Back ground noise:23 dB(A) Max, Fix the motor in a test jig (Shaft Horizontal). Microphone is faced to the flat of motor and recedes by 10cm

|

≤ 65dB(A) |

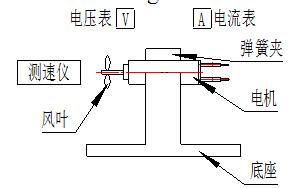

6. 电气性能 Electrical characteristics

|

序号NO. |

项目

Item |

测试环境条件

Environmental condition |

规格

Specification |

|

6-1 |

空载电流

No-Load current |

At Rated voltage and no load

额定电压及无负荷下测试 |

320mA MAX |

|

6-2 |

空载转速

No-Load speed |

43000rpm±15 %r.p.m |

|

6-3 |

额定负荷

Rated Load |

额定电压及标准负荷下测试

At Rated voltage and rated load

|

模拟风叶 |

|

6-4 |

额定电流Rated current |

3400 mA MAX |

|

6-5 |

额定转速Rated speed |

31500rpm±10 %r.p.m |

|

6-3 |

堵转电流

Stall current |

额定电压及锁定电机轴条件下测试

At rated voltage and shaft lock |

16A MAX |

|

6-4 |

绝缘电阻

Insulation resistance |

在 100V 直流电压下,电机引线与外壳间测量.

At DC 100V, measured between housing case and terminal. |

10MΩ Min |

7. 信赖性试验 Reliability Test

|

序号NO. |

项目

Item |

试验条件

Test condition

|

判定基准

Requirements

|

|

7-1 |

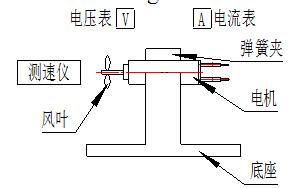

寿命测试

Life test |

1. 环境条件Condition of temperature:

常温常湿

Normal temperature and humidity

2. 试验状态Test state:

将电机固定在测试装置上(机身水平)

Fix the motor in a test jig (keep the body of the motor horizontal)

3. 测试电压Voltage: DC 9.0V

4. 负荷Load: 模拟风叶

5. 测试模式Test mode:

运行8分钟停10分钟,20个周期

8min ON 10min OFF, 20 |

在常温常湿下放置2h后,马达应符合项8-1的要求。

After 2 hours exposure in ordinary temperature and humidity, Motors shall be approved as specified in item 8-1. |

|

7-2 |

低温放置

Low temperature storage |

温度/Temperature: -20±2℃;

时间/Time: 72h

湿度/Humidity:常湿/ Ordinary Humidity |

在常温常湿下放置4h后,马达应符合项8-2的要求。

After 4 hours exposure in ordinary temperature and humidity, Motors shall be approved as specified in item 8-2. |

|

7-3 |

高温放置

High temperature exposure |

温度/Temperature: 60±2℃;

时间/Time: 72h

湿度/Humidity:常湿/ Ordinary Humidity |

|

7-4 |

湿度测试Humidity test |

温度/Temperature: 40±2℃;

时间/Time: 72h

湿度/Humidity:90±5%RH |

|

7-5 |

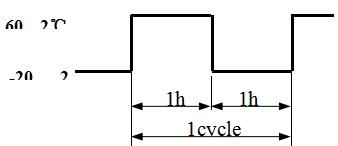

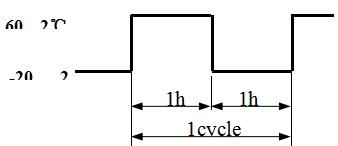

热冲击试验Thermal Shock

test |

温度Temperature :-20℃~ 60℃

时间Time:2h

循环周期数Circle cycle:10cycles

|

在常温常湿下放置4h后,马达应符合项8-3的要求。

After 4 hours exposure in ordinary temperature and humidity, Motors shall be approved as specified in item 8-3. |

|

7-6 |

跌落试验

Drop test |

方向Direction:x,y,z

高度High: 1.5m

跌落次数: 每个方向各2次

Times:2 times each direction

试验状态: 将电机放在重约100克的刚性较好的塑料盒子里,自由地跌落至混凝土地面上

Test state: The motor is set into a rigid cubic plastic housing approximately weight 100g and fall free on the concrete floor |

试验结束后,电机应满足8-1的规定After having finished the test, the motor should conform to the requirements of the items 8-1. |

8.

信赖性试验后的要求 Requirement After Reliable Test

|

序号NO. |

项目

Item |

规格

Specification |

|

8-1 |

TABLE A |

1) 额定转速/Rated speed:初始值/ Initial data±50% MAX

2) 额定电流/Rated current:初始值/ Initial data±50% MAX

3)绝缘阻抗/Insulation resistance:10MΩ Min

4)起动电压/ Starting voltage:1.5V DC Max |

|

8-2 |

TABLE B |

1) 额定转速/Rated speed:初始值/ Initial data±30% MAX

2) 额定电流/Rated current:初始值/ Initial data±30% MAX |

|

8-3 |

TABLE C |

1) 额定转速/Rated speed:初始值/ Initial data±35% MAX

2) 额定电流/Rated current:初始值/ Initial data±35% MAX |

9. 包装要求 Package Require

NO.

序号 |

Item

项目 |

Specification

规格(L*W*H) |

Inner parts name and quantity

内装件品名及数量 |

|

9.1 |

Tray

内包装盒 |

297×223×21 |

Motor

电机 |

100pcs |

|

9.2 |

Inner box

内包装箱 |

300×225×230 |

Tray

内包装盒 |

10pcs |

|

9.3 |

Outer box

外包装箱 |

310×238×240 |

Inner box

内包装箱 |

1pcs |

10. 注意事项 CAUTIONS

1) 使用容差 ALLOWABLE RANGE FOR USE

注意电压及电流的使用范围,并且在本标准规定情况下使用电机,否则将相应降低电机的使用

寿命和性能。

Pay attention to voltage and current ranges for use ,and use the vibration motor in the condition

accordance with this specifications ,or the life and performance should be considerably reduced.

2) 电机测试 MOTOR TESTING

额定数据的测试应在马达水平放置且被固定的状态下进行.

电机在运输过程中应小心轻放,避免严重碰撞敲击引起的电机机身和性能受损。

Tests related to rated rpm and to rated current are to be measured holding the motor in a horizontal posture.

3) 储存 STORAGE

马达应适当的操作、储存和运转环境中均不可存在腐蚀性气体。例如:H2S、SO2、NO2、CL2

等。另外存储环境中不可有诸如硅、氰、甲醛水和苯酚等能放射出腐蚀性气体的物质,在电机

的机械构造或装置中,如果存在腐蚀性气体,那么这会引起马达不运转。

For proper operation. storage and operating environment must not contain corrosive gases. For

example H2S. SO2. NO2. CL2. etc. In addition storage environment must not have materials that emit

corrosive gases especially from silicon. cyanic. formalin and phenol group. In the mechanism or the

set. existence of corrosive gases may cause no rotation in motor.

4) 使用电机 HANDLING OF MOTOR 小心拿取、使用。

避免放置在磁性物体附近或接触其表面,这将影响其功效。

注意操作环境,尤其注意若铁粉被磁铁吸附,将出现噪音问题,降低使用寿命

-to handle and hold the vibration motor case softly.

-do not bring magnetized object near or contact with the surface of motor to avoid of performance

being deteriorated.

-pay attention to the handling and working environments of motor, because such objects as iron

powder if attracted by motor magnet,will cause noise characteristic deterioration, thus reducing the

reliability.

请勿靠近磁体或有磁场的装置存放或运行电机

Please do not operate or store the motor near magnet or magnetic devices.

请在6个月内使用,请不要在高温、低温、高湿环境下存储。在使用和打开马达外包装时请避

免水气凝结。

Make arrangement to limit the storage period to 6 months or less. Please do not store motor in high

temperature. Low temperature. high humidity environment. Condensation of atmosphere must be

avoided in motor usage or opening the packaging of the motor.

5)安装您的电机 MOUNTING YOUR MOTOR:

部分坤鹏达电机都在电机定子上提供了安装孔用来安装您的电机,请注意不要使用过长的螺钉以避免损坏电机内部元件。

Some KINGWE motors provide tapped holes in the motor housing for you to use to mount your motor. Please take care not to use screws so long that they can interfere with components inside the motor.

轴承固定座也是用来安装您的电机的,对此安装区域请避免过度用力。

Bearing bosses are also used for mounting motors. Please avoid excessive clamping forces on these areas.

在安装电机时,请尽量不要完全紧贴或包住电机,应为电机留出散热空间。

When mounting your motor, please try not to completely close or around the motor, motor should be set aside space for heat dissipation

最好不要利用电机表面的特征来固定电机,例如:通风孔。这样将可能会改变这些特征。

It is preferable not to use features on the motor such as ventilation holes for location means. It is possible that these features may change as new or modified tooling is used in the future.

如未咨询我司,装入贵司产品中的电机上的任何通风孔都不可以堵死。

Any ventilation holes in the motor should not become blocked in your product without consultation with KINGWE.

如果使用粘合剂安装电机,必须注意粘合剂不能进入轴承区域或电机内部。

If adhesives are to be used to mount you motor care must be taken to avoid any adhesive getting into the bearing areas or motor.

6) 焊接 Soldering:

不论使用任何方式将您的电源连接到您的电机,请注意不能用过大的力或过高的温度,否则会造成电机内部零件变形。

Whatever means you are to use to connect your supply to your motor please take care not to use so much force or heat that you cause distortion to components inside the motor.

电机端子接线焊锡温度:350℃ 焊锡时间:1~2秒

Motor terminal Soldering temperature:350℃, Soldering time:1~2sec.

7) 电机连轴 COUPLING YOUR MOTOR:

装配过程中,如果电机出轴端欲衔接齿轮、风叶等其它配件,请牢记,如果安装不当,电机运转时一种非正常的径向或轴向负荷将通过连接加载到电机,这种负荷将对轴承寿命造成严重影响。如果您对此有任何担心,请咨询我司。

If you intend to couple a gear or a fan or some other item to your motor shaft during assembly, always remember that unusual radial and axial loads transmitted to the motor from the coupling during operation of the motor can have serious effects on the life of the bearings. If you have any concerns about this please consult with KINGWE.

8) 过负荷 OVERLOADS:

体积小、功率高的电机通常温升高;如未咨询我司,使用时请注意不能加过高的电压,不能运行在堵转或接近堵转状态过长时间。

Small high power motors are subject to very fast temperature rises. Take care not to apply excessive voltage to the motor or to operate it at stall or near stall for prolonged periods without first consulting with KINGWE.

9) 危险环境 HAZARDOUS ENVIRONMENTS:

我司电机在正常环境中的抗腐蚀能力是符合要求的,但机壳上有少许区域存在的裸露金属对腐

蚀比较敏感,因此未经咨询请不要在腐蚀环境中储存或使用电机。

The degree of protection against corrosion on KINGWE motors is satisfactory only for normal

environments. There are small sections of the housing in which some bare metal is exposed and is

susceptible to corrosion. It is advisable not to store or use motors in corrosive environment without

consultation with KINGWE.

10) 其它说明 OTHER

马达轴向间隙处不应有杂物(如颗粒、纤维物、头发、胶带、胶水等)

There should be no sundries (such as grain, fibre, hair, small tape, glue etc.) in the shaft end play.

当换向器和电刷接触时,电机会发出轻微的电噪音

The motor may cause slight electronic noise due to the contact between brush and commutator.

电机内部有很强力的磁铁,所以机壳表面也存在磁力

The motor has a strong magnet so please be aware that it has a magnetic force on the surface of the bracket.

外壳表面或边缘有少许斑点是允许的

It is allowable to have a few spots on the surface or edge of case.

11. 附件 ATTACHMENT

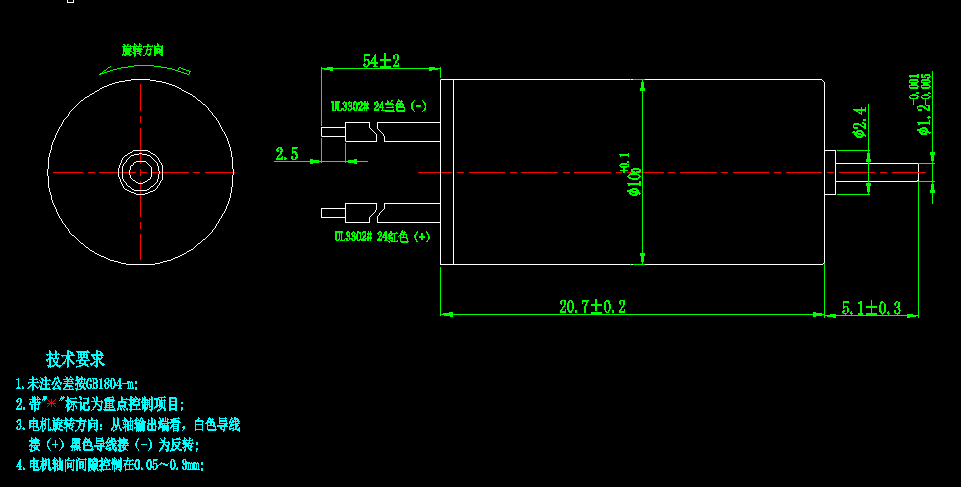

1) 电机外形图 Motor Outline Drawing

—————— END ——————